Products

-

Current position:Home - Products

RCO-RTO- Activated Carbon Adsorption and Desorption System

Product description

Equipment introduction:

Activated carbon adsorption tower is a high-efficiency, economical and practical type of organic waste gas purification and treatment device; it is an environmental protection equipment product that filters and absorbs offensive odors; it is a traditional process widely used in organic tail gas treatment, such as benzene, alcohol , Ketones, ethers, alkanes, aldehydes, phenols, and other volatile gases, widely used in chemical, machinery, printing, rubber, furniture, mechanical and electrical, marine, automotive, petroleum and other industries.

Adopting adsorption tower processing, mature technology, stable operation and good processing effect. At the same time, according to the characteristics of the exhaust gas produced in different processes, such as the exhaust gas temperature, whether it contains oil mist, dust and other related parameters, a pre-treatment device or functional section such as a cooler and a filter is built in or added to the inlet of the exhaust equipment. The adsorption section is well protected to ensure that the adsorption tower operates in a highly efficient state with high adsorption efficiency and meets national environmental protection requirements.

Equipment structure:

The adsorption tower contains the following components:

1、The tower body part of the adsorption tower contains: maintenance ladder, maintenance manhole, base and so on.

2、The adsorption layer part contains: punching plate, adsorption material import and export, emergency passage;

3、Detection system contains: differential pressure gauge, pressure relief rupture disc, temperature sensor, etc .;

working principle:

Adsorption process: Due to the presence of unbalanced and unsaturated molecular gravity or chemical bonding forces on the solid surface, when this solid surface is in contact with gas, it can attract gas molecules, make them condensed and remain on the solid surface. This phenomenon is called For adsorption. Utilizing the adsorption capacity of the solid surface, the exhaust gas is brought into contact with the porous solid material on the large surface, and the pollutants in the exhaust gas are adsorbed on the solid surface to separate it from the gas mixture to achieve purification purposes. The exhaust gas enters the top of the adsorption tank after removing the small suspended particles through the air filter. After the activated carbon is adsorbed in the tank, the harmful components are removed, and the purified gas that meets the emission standards is discharged to the outside through the fan.

Characteristics of adsorption tower:

1、High adsorption efficiency and strong capacity;

2、The equipment has a compact structure, a small footprint, simple and convenient maintenance and management, and low operating costs;

3、Capable of processing multiple mixed organic waste gases simultaneously;

4、Adopt automatic control operation design, easy and safe operation;

5、Fully enclosed type, can be used indoors and outdoors

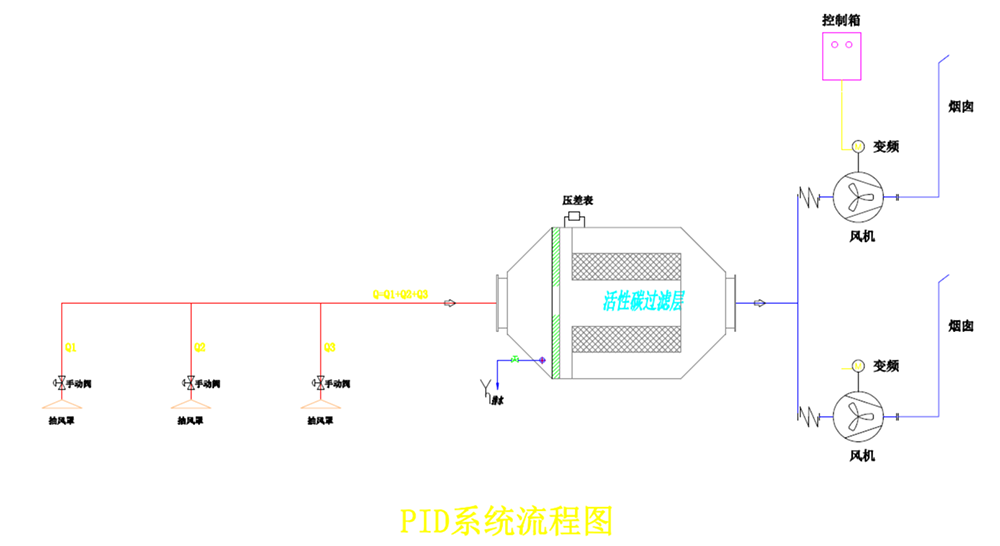

flow chart:

Activated carbon adsorption tower is a high-efficiency, economical and practical type of organic waste gas purification and treatment device; it is an environmental protection equipment product that filters and absorbs offensive odors; it is a traditional process widely used in organic tail gas treatment, such as benzene, alcohol , Ketones, ethers, alkanes, aldehydes, phenols, and other volatile gases, widely used in chemical, machinery, printing, rubber, furniture, mechanical and electrical, marine, automotive, petroleum and other industries.

Adopting adsorption tower processing, mature technology, stable operation and good processing effect. At the same time, according to the characteristics of the exhaust gas produced in different processes, such as the exhaust gas temperature, whether it contains oil mist, dust and other related parameters, a pre-treatment device or functional section such as a cooler and a filter is built in or added to the inlet of the exhaust equipment. The adsorption section is well protected to ensure that the adsorption tower operates in a highly efficient state with high adsorption efficiency and meets national environmental protection requirements.

Equipment structure:

The adsorption tower contains the following components:

1、The tower body part of the adsorption tower contains: maintenance ladder, maintenance manhole, base and so on.

2、The adsorption layer part contains: punching plate, adsorption material import and export, emergency passage;

3、Detection system contains: differential pressure gauge, pressure relief rupture disc, temperature sensor, etc .;

working principle:

Adsorption process: Due to the presence of unbalanced and unsaturated molecular gravity or chemical bonding forces on the solid surface, when this solid surface is in contact with gas, it can attract gas molecules, make them condensed and remain on the solid surface. This phenomenon is called For adsorption. Utilizing the adsorption capacity of the solid surface, the exhaust gas is brought into contact with the porous solid material on the large surface, and the pollutants in the exhaust gas are adsorbed on the solid surface to separate it from the gas mixture to achieve purification purposes. The exhaust gas enters the top of the adsorption tank after removing the small suspended particles through the air filter. After the activated carbon is adsorbed in the tank, the harmful components are removed, and the purified gas that meets the emission standards is discharged to the outside through the fan.

Characteristics of adsorption tower:

1、High adsorption efficiency and strong capacity;

2、The equipment has a compact structure, a small footprint, simple and convenient maintenance and management, and low operating costs;

3、Capable of processing multiple mixed organic waste gases simultaneously;

4、Adopt automatic control operation design, easy and safe operation;

5、Fully enclosed type, can be used indoors and outdoors

flow chart:

-

- Fitter Environmental

- Professional air pollution prevention manufacturer

-

- ABOUT US

- Company

- Development

- Culture

- Advantage

- Honor

-

- VIDEO

- Video

-

- RECRUITMENT

- Recruitment

- Development

- Culture

- Advantage

- Honor

-

- CONTACT

- Contact us

- Message

Copyright @ 2019 Copyright Kunshan Feitter Environmental Technology Co., Ltd. Su ICP:15006502-1 Technical Support:昆山网站设计

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd.

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd. Hotline:0512-36904088

Hotline:0512-36904088