Products

-

Current position:Home - Products

Bag dust collector

Product description

Adapted concentration: 0-1000g / m3

Air volume: 5000 --- 500000m3 / h

Processing technology: bag type online pulse dust removal / bag type offline pulse dust removalEmission Standard: "Emission Standard for Odor Pollutants" GB14554--93

"Integrated Emission Standards for Air Pollutants" GB16297-1996"Design Sanitary Standards for Industrial Enterprises" GBZ1-2010

"Technical Specifications for Monitoring Exhaust Gas from Fixed Sources" (HJT 397-2007)Reference standard: General technical specifications of bag dust removal engineering

GB-4053.1-93-Safety technical requirements for fixed steel ladder

"Bag Dust Collector Technical Requirements and Acceptance Specifications" (JB / T 8471-2010)

《Pulse injection type dust collector》 JB / T 8532-2008

Equipment introduction:

The small and medium-sized pulse dust collector is an advanced high-efficiency bag type dust removal equipment. It is a small and medium-sized dust removal equipment with good dust removal effect, high dust removal efficiency, reliable operation, convenient maintenance and small footprint.

Small and medium-sized pulse dust collectors are generally used in air purification and material recovery in electronics, chemical, plastic, cement, powder, food, mold, machinery and hardware industries.

FMD series dust removal system main features:

Dust removal method: dust collection equipment adopts automatic pulse dust removal method

Filtering method: bottom inlet air filter

Pressure type in the dust collector: The filter room of the dust collector is negative pressure. The dust collector is set at the inlet end of the fan, so that the dust collector operates under negative pressure. After the dust-containing gas is purified by the filter cloth, it is discharged by the fan through the chimney. The gas entering the fan of the negative pressure dust collection system is clean gas, which has less wear on the fan impeller and prolongs the service life of the fan.

Performance of dust collection equipment:

1. Cartridge dust collector is a typical high-efficiency dust collector, which can be used to purify particles with a particle size of 0.1 μm.

2. For the above dust-containing gases, the dust removal efficiency can generally reach more than 99.5%, and the performance is stable and reliable, and the operation is simple.

3. Strong adaptability, can capture dust of various properties, and will not affect the dust removal efficiency due to dust specific resistance and other properties.

4. Easy to recycle dust, no sludge treatment, wastewater pollution and other problems, simple maintenance.

5. Scope of application: It is applicable to the collection of various types of powders, such as the dust collection of various production equipments in the chemical industry, food industry, pharmaceutical industry, electronics industry, etc., and it can also effectively handle steel, non-ferrous metals, mining, and various furnaces. Use dust collection and various drying, stirring, mixed exhaust dust collection treatment.

6. According to the actual situation or customer requirements, the equipment can be designed as explosion-proof or non-explosion-proof.

working principle

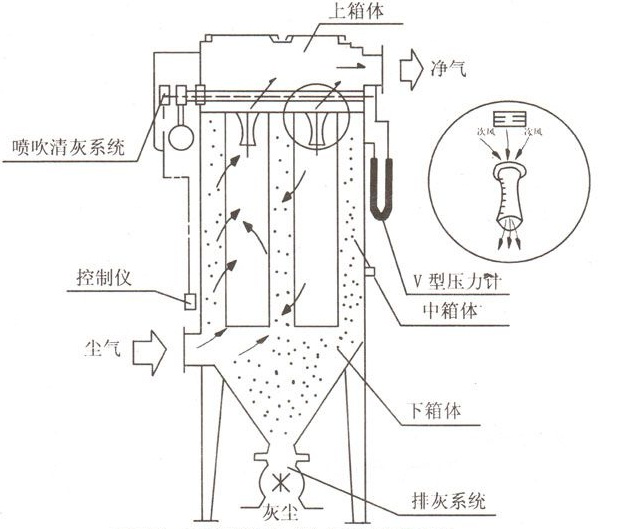

After the dust-containing gas enters the dust hopper of the dust collector, due to the sudden expansion of the air flow section and the role of the air distribution plate, some coarse particles in the air flow settle in the ash hopper under the action of dynamic and inertial forces; fine-grained and low-density dust particles enter the dust filter Through the combined effects of Brownian diffusion and sieving, dust is deposited on the surface of the filter material, and the purified gas enters the clean room and is discharged by the exhaust pipe through the fan.

The resistance of the bag filter increases with the thickness of the dust layer on the surface of the filter material. When the resistance reaches a certain value, the dust is cleaned. At this time, the PLC program-controlled pulse valve is opened and closed, and then the electromagnetic pulse valve is opened. The compressed air and the rapid expansion in the upper case quickly flow into the filter cartridge, causing the filter cartridge to expand and deform to generate vibration, and under the action of reverse airflow scouring The dust attached to the outer surface of the filter bag was peeled and dropped into the ash hopper. After the ash cleaning is completed, the electromagnetic pulse valve is closed and the filtering state is restored, and the shed dust is dropped into the ash hopper and discharged through the ash valve.

work flow chart:

-

- Fitter Environmental

- Professional air pollution prevention manufacturer

-

- ABOUT US

- Company

- Development

- Culture

- Advantage

- Honor

-

- VIDEO

- Video

-

- RECRUITMENT

- Recruitment

- Development

- Culture

- Advantage

- Honor

-

- CONTACT

- Contact us

- Message

Copyright @ 2019 Copyright Kunshan Feitter Environmental Technology Co., Ltd. Su ICP:15006502-1 Technical Support:昆山网站设计

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd.

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd. Hotline:0512-36904088

Hotline:0512-36904088