Products

-

Current position:Home - Products

Equipment introduction:

Activated carbon organic solvent recovery device uses high-quality activated carbon as the adsorption medium, adopts microcomputer full automatic control, and adopts vibration damping, sound insulation, explosion protection, over temperature and over pressure protection measures. It has good safety, weight, and small footprint. The operation is simple, and it is a set of environmental protection and energy saving equipment for the purification of organic gas and the recovery of organic solvents.

Activated carbon organic solvent recovery device absorbs and recovers the exhaust gas of benzene, alcohol, ketone, ester, ether, alkane, phenol, gasoline and other organic solvents. Light industry, printing, rubber, furniture, mechanical and electrical, automotive, petroleum and other industries.

The device is suitable for high-concentration, single-gas waste gas. Adsorption and recycling of organic waste gas by granular activated carbon are of high economic benefits.

Equipment structure:

The adsorption tower is composed of an upper box, a lower support, a working ladder, a platform guardrail and a discharging device.

The activated carbon tower type can be designed as: magazine type, horizontal type, round barrel type. Material can be made with SUS304, SS41, etc. The commonly used filled activated carbons are coconut shell and coal-based activated carbon. The interior has been treated with anti-corrosion. It has resistance to strong acid and alkali and salt corrosion. It will not be oxidized and corroded by other factors under long-term operation and use. The thickness of the main structure must be determined according to each model and processing capacity, and it must have sufficient reinforcement to bear the load required for the structure and operation, and provide the necessary operating platform.

This device mainly includes: adsorption tanks, shut-off valves, filters, separation gas cylinders, centrifugal fans, and other equipment, which are automatically equipped with electronically controlled pneumatic inlet adjustment valves.

working principle:

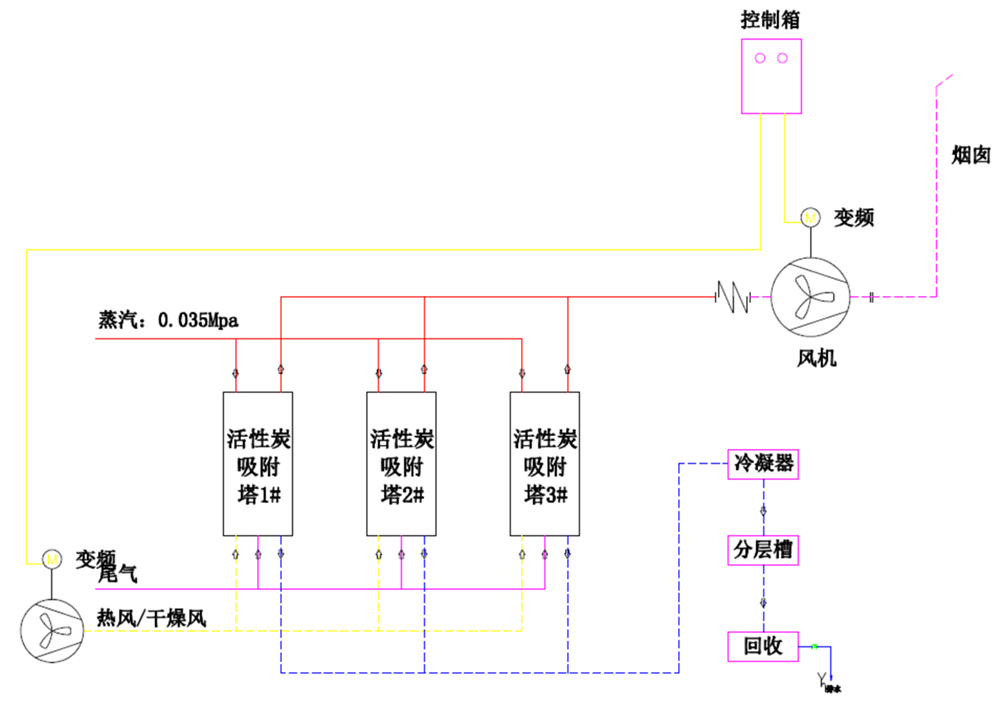

The adsorption device uses activated carbon with many micropores and a large specific surface area, and uses the characteristics of molecular gravity and capillary action to make organic gas vapor and volatile substances adsorb on its surface. Under vacuum and other conditions, the adsorbed substance is precipitated. The device uses steam as a desorption medium, and the organic solvent vapor that is resolved together with water vapor is condensed through a condenser and enters a separator for separation, and the organic solvent is recovered by heavy recovery.

The device is composed of two adsorption tanks, and the two tanks are alternately desorbed by using one suction and one desorption. The device is composed of three adsorption tanks. According to the process, using two tanks for simultaneous suction and simultaneous removal can increase the amount of processing air and reduce equipment investment. A rod-shaped activated carbon with a large specific surface area is set in the tank, the exhaust gas enters the activated carbon, the organic solvent is trapped by the activated carbon, and the purified gas is discharged out of the equipment through the exhaust fan.

After the device is used for a period of time, the capillaries on the surface of the activated carbon are filled with organic solvents. At this time, the activated carbon needs to be regenerated to restore its adsorption characteristics. The desorption medium is steam: the pressure of the steam source is adjusted to 0.035-0.05 MPa and enters the tank. Using its physical properties, the organic solvent is resolved from the activated carbon, enters the condenser to condense, forms a condensate, and flows into the separation aeration cylinder. After heavy separation, the organic solvent is recovered, and the remaining liquid is discharged after aeration.

Equipment composition: The equipment consists of two major systems: adsorption and desorption. The adsorption system consists of two adsorption tanks A and B, a closed control valve and an induced draft fan at the inlet and outlet. Desorption consists of steam system, fire prevention and cooling system, over-temperature alarm system; aeration system, liquid separation system, recovery system, etc. The electrical control cabinet controls the operation of the two systems of adsorption and desorption.

Characteristics of adsorption tower:

1、High adsorption efficiency, strong capacity, high recycling efficiency, energy saving and environmental protection;

2、Compact equipment structure, simple and convenient maintenance and management, and low operating cost;

3、Capable of processing multiple mixed organic waste gases simultaneously;

4、Adopt automatic control operation design, easy and safe operation;

5、Can be designed according to actual conditions, strong plasticity

flow chart:

-

- Fitter Environmental

- Professional air pollution prevention manufacturer

-

- ABOUT US

- Company

- Development

- Culture

- Advantage

- Honor

-

- VIDEO

- Video

-

- RECRUITMENT

- Recruitment

- Development

- Culture

- Advantage

- Honor

-

- CONTACT

- Contact us

- Message

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd.

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd. Hotline:0512-36904088

Hotline:0512-36904088