Products

-

Current position:Home - Products

UV photolysis low temperature plasma processing system

Product description

Photocatalytic oxidation treatment equipment

Nano photocatalytic oxidation process principleOn the surface of a support where a nano photocatalyst (such as a nano TiO2 photocatalyst) exists at normal temperature, under the irradiation of light (generally the ultraviolet light C band 254nm), it will excite the photoelectrons (e-) and Reducing photo-generated holes (h +), and highly active hydroxyl radicals [HO], superoxide radicals [HO], [O], etc., perform a series of intense photochemistry and catalysis with organic pollutants in exhaust gas The oxidation-reduction reaction finally degrades organic pollutants (partial inorganic substances) to produce stable harmless inorganic substances, CO2, H2O, etc.

Nano Photocatalytic Oxidation Treatment Features:

1、High-efficiency, nano-catalyst mesh processed by a special process, the particle size of this nano-catalyst is only about 5um, and its surface area is 3-10 times larger than that of ordinary catalyst mesh. Its photocatalytic efficiency is also significantly improved. The catalyst uses various metal oxides such as titanium dioxide Doping can be effectively excited at a longer wavelength (388nm) to catalyze and oxidize exhaust gas components, and efficiently treat exhaust gas components;

2、The combination of energy saving, photocatalysis and UV photolysis, on the one hand, increases the output of high-energy short-wave, and on the other hand, improves the utilization of purple light and long-wave ultraviolet light in combination with nano-catalytic networks, greatly reducing energy consumption;

3、Low operating cost and low maintenance;

4、Small size, light weight and small footprint;

5、Compact structure, stable and safe operation;

6、Small wind resistance can greatly reduce fan power;

The mechanism of using high-voltage pulsed corona plasma to remove organics from exhaust gas is: in a plasma generator, a non-equilibrium plasma is obtained at normal temperature through a high-voltage pulse discharge with a steep front edge and a narrow pulse width (ns), which generates a large amount of high energy Electron and strong oxidizing active particles such as O ·, HO2 ·, HO ·, etc., perform oxidative degradation reaction on organic molecules, so that the organic materials are finally converted into harmless CO2 and H2O.

Process:

After pretreatment of exhaust gas containing dust, water vapor and impurities, the negative pressure of the induced draft fan enters the main body of the low-temperature plasma equipment, and the main body passes through the plasma generator under the action of high-frequency pulses and special-structured generators. The electron (10ev) bombards a series of reactions such as ionization, cracking, and oxidation at a frequency of several million times per second, which decomposes macromolecular organic matter into small molecule organic matter, and small molecule organic matter is directly converted into H2O and CO2 and is directly emitted.

1、High-efficiency, nano-catalyst mesh processed by a special process, the particle size of this nano-catalyst is only about 5um, and its surface area is 3-10 times larger than that of ordinary catalyst mesh. Its photocatalytic efficiency is also significantly improved. The catalyst uses various metal oxides such as titanium dioxide Doping can be effectively excited at a longer wavelength (388nm) to catalyze and oxidize exhaust gas components, and efficiently treat exhaust gas components;

2、The combination of energy saving, photocatalysis and UV photolysis, on the one hand, increases the output of high-energy short-wave, and on the other hand, improves the utilization of purple light and long-wave ultraviolet light in combination with nano-catalytic networks, greatly reducing energy consumption;

3、Low operating cost and low maintenance;

4、Small size, light weight and small footprint;

5、Compact structure, stable and safe operation;

6、Small wind resistance can greatly reduce fan power;

Low temperature plasma processing equipment

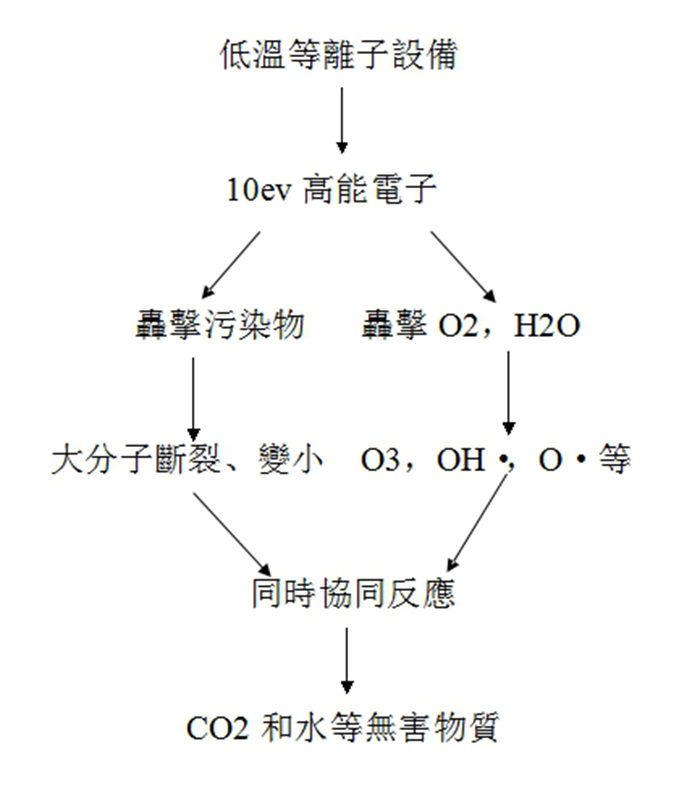

Equipment introduction:The mechanism of using high-voltage pulsed corona plasma to remove organics from exhaust gas is: in a plasma generator, a non-equilibrium plasma is obtained at normal temperature through a high-voltage pulse discharge with a steep front edge and a narrow pulse width (ns), which generates a large amount of high energy Electron and strong oxidizing active particles such as O ·, HO2 ·, HO ·, etc., perform oxidative degradation reaction on organic molecules, so that the organic materials are finally converted into harmless CO2 and H2O.

Process:

After pretreatment of exhaust gas containing dust, water vapor and impurities, the negative pressure of the induced draft fan enters the main body of the low-temperature plasma equipment, and the main body passes through the plasma generator under the action of high-frequency pulses and special-structured generators. The electron (10ev) bombards a series of reactions such as ionization, cracking, and oxidation at a frequency of several million times per second, which decomposes macromolecular organic matter into small molecule organic matter, and small molecule organic matter is directly converted into H2O and CO2 and is directly emitted.

Features:

1、One-time investment, using only electricity to process pollutants, the plasma generator is durable and has no consumables;

2、No secondary pollution, the pollutants are converted into harmless substances such as water and carbon dioxide by ionizing and decomposing the pollutants, and the harmful pollutants are truly eliminated;

3、High treatment efficiency, the highest treatment efficiency can be as high as 98% or more, which is more advantageous for the difficult exhaust gas treatment effect;

4、Low resistance, which can greatly reduce the power of the exhaust fan, reduce investment costs and operating costs, and reduce the noise of high-power fans;

5、Small size, light weight, small footprint, suitable for environments with limited installation, tight land occupation and limited load bearing;

6、Maintenance-free and simple operation;

1、One-time investment, using only electricity to process pollutants, the plasma generator is durable and has no consumables;

2、No secondary pollution, the pollutants are converted into harmless substances such as water and carbon dioxide by ionizing and decomposing the pollutants, and the harmful pollutants are truly eliminated;

3、High treatment efficiency, the highest treatment efficiency can be as high as 98% or more, which is more advantageous for the difficult exhaust gas treatment effect;

4、Low resistance, which can greatly reduce the power of the exhaust fan, reduce investment costs and operating costs, and reduce the noise of high-power fans;

5、Small size, light weight, small footprint, suitable for environments with limited installation, tight land occupation and limited load bearing;

6、Maintenance-free and simple operation;

-

- Fitter Environmental

- Professional air pollution prevention manufacturer

-

- ABOUT US

- Company

- Development

- Culture

- Advantage

- Honor

-

- VIDEO

- Video

-

- RECRUITMENT

- Recruitment

- Development

- Culture

- Advantage

- Honor

-

- CONTACT

- Contact us

- Message

Copyright @ 2019 Copyright Kunshan Feitter Environmental Technology Co., Ltd. Su ICP:15006502-1 Technical Support:昆山网站设计

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd.

Welcome to the official website of Kunshan Feitter Environmental Technology Co., Ltd. Hotline:0512-36904088

Hotline:0512-36904088